When your brand makes a product and it comes to selling the very first thing that you have to notice is your packaging. And when it comes to choosing to package your product you have come across many options.

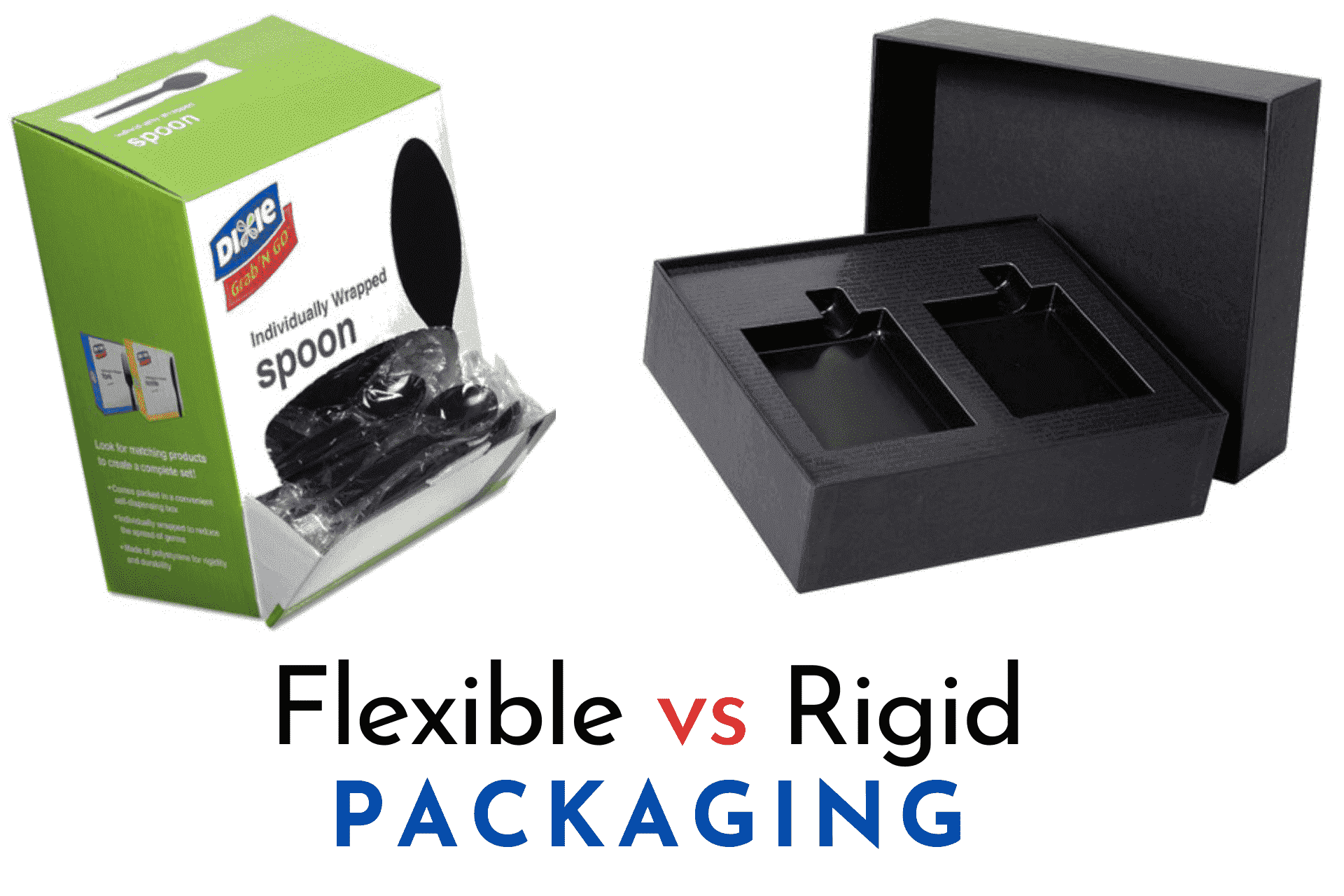

So, it might be overwhelming to find the perfect packaging material. There are two broad packaging categories that you will find, one is flexible and the other is rigid.

But what are the differences between these two packaging materials and which is better for what kind of product is the main thing to see? So both flexible and rigid box packaging have their advantages and disadvantages and this article will help you to understand which is a better choice for your specific packaging needs.

What is Flexible Packaging?

The packaging material is meant to bend, flatten, or reshape in any form. It is a type of packaging that is made of polymers or plastic that can be shaped to fit the product. It is a lightweight, strong, and easy-to-transport material.

Flexible plastics are high-density polyethylene and they can be molded into any shape and are resistant to tears and punctures. It is commonly used for products like coffee, tea, sweets, dried fruits, snacks, and many more.

What is Rigid Packaging?

Rigid packaging is any kind of packaging that is meant to hold its shape even under harsh conditions. The material used in this form of packaging is cardboard containers, hard plastic, glass, metal, and so on. This type of packaging is typically more expensive than any other type of packaging because you cannot easily destroy it. Some examples of rigid boxes include pickle jars, hard plastic cannabis, wine bottles, hummus containers, and many more.

Both flexible and rigid have pros and cons. The followings are the main advantages and disadvantages of flexible packing as compared to rigid packing.

Advantages:

The followings are the advantages of flexible packing over rigid packing.

Weight:

Flexible packaging is lighter in weight as it is made of lighter material than a rigid one. It can be lifted easily and can transport from one place to another at any time. While rigid packing is heavier than flexible one because it is made of thicker material that is heavy. Flexible packaging materials are gaining swiftly over rigid due to their lower expense and environmental impact.

Size:

Flexible packing is smaller in size and which makes it lighter in weight than a rigid one. As this packaging is lighter in shape and size it can simplify transportation manner as you can transfer any kind of box because of its smaller size. While rigid is packed in rigid material like bottles that cost more because of the full weight of the bundle.

Sustainability:

Flexible packaging typically requires less material than rigid and even this packaging has less waste than a rigid one. Moreover, it offers more recycled materials such as kraft paper than rigid packaging material.

Brand Impact:

Your brand product stands out from the competition when you are using flexible packing rather than rigid packing. Such as using stand-up bags rather than traditional rigid ones has a good impact on the customers. Stand-up pouches made with natural crafts papers attract more customers to come and buy a product that looks more appealing.

Environmentally Friendly:

One of the advantages of flexible packaging is that it takes less space in landfills and has the lowest carbon footprint than rigid packaging material. Moreover, this type of packaging needs less water and electricity to fabricate and ship and it generates a small portion of a greenhouse gas than rigid packaging materials.

Disadvantages:

The followings are the disadvantages of flexible over rigid packaging material.

Lack of Pressurization:

One of the drawbacks of flexible packing is its lack of pressurization. For example, if you sell a product that must be contained under pressure such as soda pop flexible failed to maintain that pressure and rigid packaging is best for this purpose.

No Impact Protection:

Another drawback of flexible packaging is that some products require more impact protection than others. For example, you might have packaging of electronic wiring in flexible bags, but a delicate pre-assembled electronic device must likely needs rigid packaging. So, for protection, a rigid packing material is better than a flexible one.

Lacking Superior Strength:

As the flexible box is made of plastic material and the rigid box material is made from hard plastic or other material like glass. So, rigid packaging is superior in strength to flexible one and this is one of the drawbacks of flexible one.

Affect the Food Flavor:

As flexible packaging is made of plastic or other materials related to plastic plastic is a health hazard material. So one of the disadvantages of using flexible packing is that plastic can be melted easily in heat which will affect the food flavor and even sometimes can destroy food.

Lack of Recyclability:

One of the drawbacks of flexible packaging is that it has a difficult recycling process. It has multilayers and it is not easy to separate them for the recycling process. Products that contain plastic paper-metal material for packaging are very difficult to recycle. So, this drawback needs certain attention in the future.

Conclusion:

So, flexible packaging has both advantages and disadvantages over rigid packaging material. And if your brand is going to sell a product you must keep in mind both advantages and disadvantages of flexible over rigid packing material.